Rising Demand For Consumer Electronics Are Going To Drive The Lithium-Ion Battery Materials Market

- December, 2023

- Chemicals & Materials

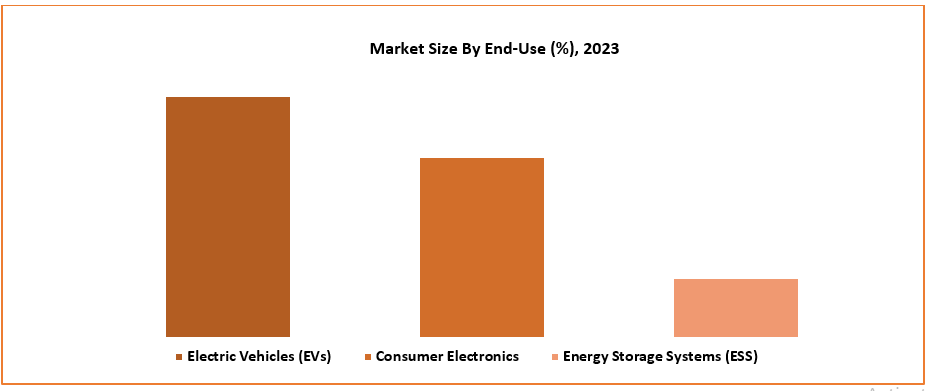

As per Intent Market Research, the Lithium-ion Battery Materials market size is expected to grow from USD 48.6 billion in 2023-e to USD 120.34 billion by 2030, at a CAGR of 13.8% during the forecast period (2024-2030). Rising renewable energy storage systems are driving the growth of the lithium ion battery materials market. Prominent players 3M, BASF SE, BTR New Material Group Co., Ltd, JFE Chemical Corporation, KUREHA CORPORATION, LANDF CORP., NEI Corporation, POSCO FUTURE M, Resonac Holding Corporation, SGL Carbon, Sumitomo Metal Mining Co., Ltd., Tanaka Chemical Corporation, Toda Kogyo Corp., UBE Corporation & Umicore.

A study by Intent Market Research predicts that the Lithium-ion Battery Materials market will grow to USD 120.34 billion by 2030, with a projected CAGR of 13.8%. The growing demand for efficient energy storage systems, both at the grid level and in individual homes, emphasizes the need for reliable solutions. Lithium-ion batteries are widely favored in these applications due to their high energy density and reliability. These factors collectively propel the market’s growth. A substantial challenge to this growth lies in the higher cost associated with raw materials and production processes for lithium-ion batteries.

Lithium Manganese Oxide (LMO) serves as a cathode material in lithium-ion batteries, specifically in certain types used for applications where cost is a crucial factor. These applications include power tools, consumer electronics, and specific stationary energy storage systems. LMO has a spinel crystal structure and belongs to the class of lithium manganese oxide cathodes. The manganese content contributes to its lower cost compared to cathodes containing cobalt. It is known for being a cost-effective option and provides good thermal stability, safety, and power capability.

The anode in lithium-ion batteries is a critical component responsible for storing and releasing lithium ions during the battery’s charging and discharging cycles. The most common material used for the anode in lithium-ion batteries is graphite, specifically a form of carbon known as graphite intercalation compounds. Graphite has traditionally served as the widely adopted material for lithium-ion battery anodes. Its crystalline structure facilitates the intercalation (insertion) of lithium ions between its layers during charging and their extraction during discharging.

Lithium-ion battery materials play a crucial role in energy storage systems (ESS), providing efficient and reliable solutions for storing electricity. Lithium-ion batteries in energy storage systems are utilized for various applications, including grid stabilization, peak shaving, renewable energy integration, and backup power. They provide a reliable and scalable solution for storing electricity in stationary applications.

European companies are investing in nickel mining projects, and efforts are being made to ensure a sustainable supply chain. Europe is actively working on establishing a circular economy for batteries, emphasizing the recycling and reuse of battery materials. European countries, including Germany, France, and the Nordic countries, are investing in research, development, and manufacturing facilities for battery materials. Additionally, regulatory measures are being implemented to support the growth of the battery industry while maintaining environmental and ethical standards. This focus on a local and sustainable battery supply chain is part of Europe’s broader strategy to become a leader in the global green economy and reduce dependency on imports from other regions.

The key players operating in the market are 3M, BASF SE, BTR New Material Group, JFE Chemical Corporation, KUREHA CORPORATION, LANDF, NEI Corporation, POSCO FUTURE, Resonac Holding Corporation, SGL Carbon, Sumitomo Metal Mining, Tanaka Chemical Corporation, Toda Kogyo, UBE Corporation & Umicore among others.