Regenerative Medicine to Drive Biofabrication Market

- December, 2023

- LifeSciences and Healthcare

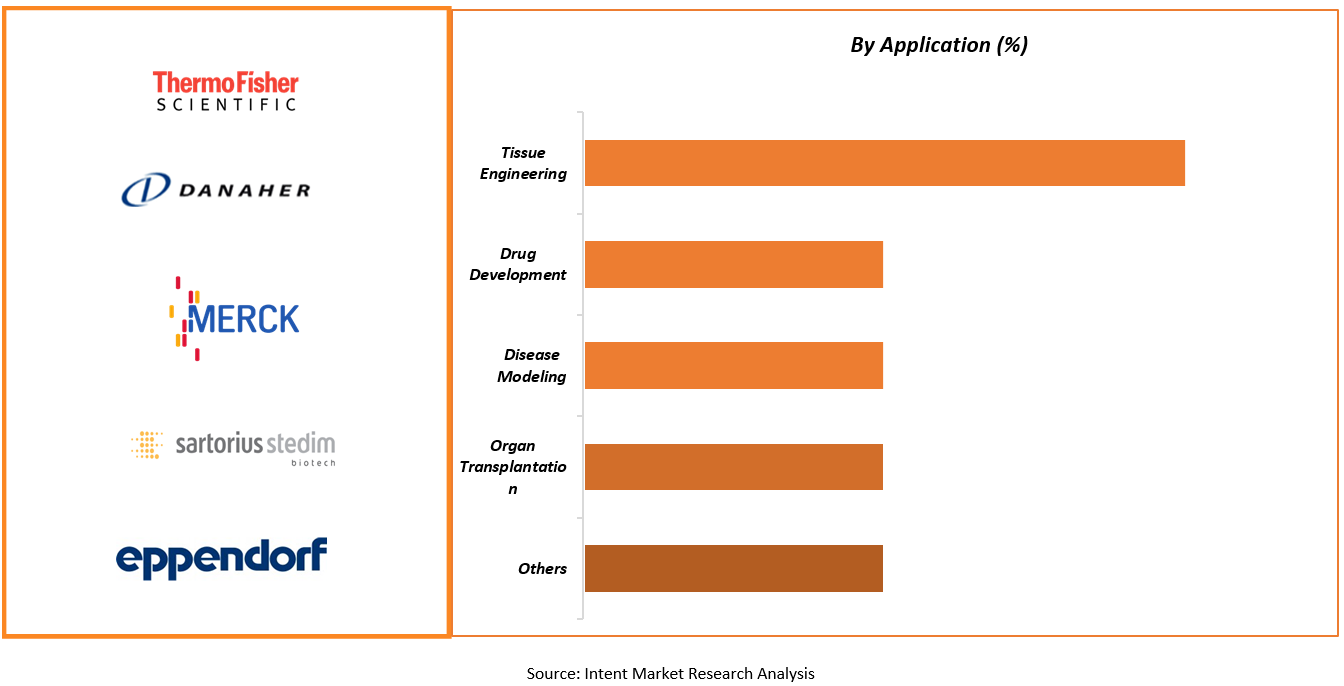

Biofabrication market size is expected to grow from USD 21 billion in 2023-e to USD XX billion by 2030, at a CAGR of 7.3% during the forecast period (2024-2030). Biofabrication market is fiercely competitive, prominent players include Danaher, Merck KGaA, Organovo Holdings, Thermo Fisher Scientific, and Sartorius Stedim Biotech.

A study by Intent Market Research predicts that the biofabrication market will grow to USD XX billion by 2030, with a projected CAGR of 7.3%. Biofabrication combines biology, engineering, and materials science to create biological structures, tissues, and organs using advanced techniques such as 3D printing. It has significant potential for applications in regenerative medicine, tissue engineering, drug testing, and disease modeling. Biofabrication can significantly reduce animal testing needs and identify potential complications associated with human clinical trials of new drugs.

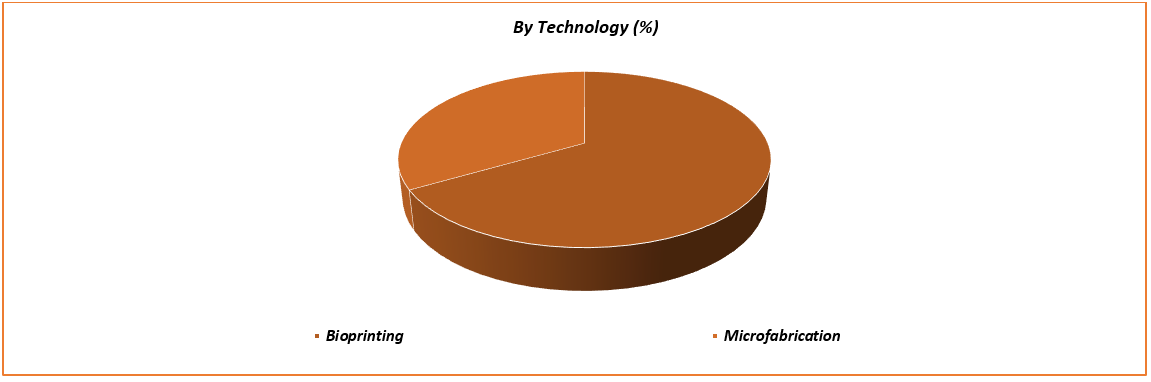

Microfabrication techniques have been pivotal in driving advancements within the biofabrication market. Microfabrication involves the precise manufacturing of structures, devices, or systems at a microscopic scale. Microfabrication techniques, such as photolithography, microfluidics, and 3D printing at high resolutions, allow the creation of intricate and customized scaffolds for tissue engineering. These scaffolds mimic the natural extracellular matrix and provide a supportive cellular growth and tissue regeneration environment.

In addition to that microfabrication enables the precise placement and patterning of cells within scaffolds or substrates. This allows researchers to create complex tissue structures by controlling the spatial arrangement of different cell types, essential for mimicking natural tissues and organs. Additionally, microfabrication techniques contribute to developing organ-on-a-chip devices, which replicate the functions of entire organs or organ systems on small chips. Allowing researchers, disease modeling, and understanding biological processes at a cellular level, reducing the need for animal testing and offering more accurate results.

Biofabrication creates 3D tissues and organs using biocompatible materials and living cells. It customizes tissues and reduces immune rejection. 3D printing and biomaterials improve the precision and feasibility of biofabricated constructs for studying diseases, drug testing, and regenerative therapies. Biofabrication has potential in wound healing, reconstructive surgery, and implants.

Biofabrication creates 3D tissues and organs using biocompatible materials and living cells. It customizes tissues and reduces immune rejection. 3D printing and biomaterials improve the precision and feasibility of biofabricated constructs for studying diseases, drug testing, and regenerative therapies. Biofabrication has potential in wound healing, reconstructive surgery, and implants.

Biotech, and pharma companies create tissue models mimicking human physiology for drug testing and advance regenerative therapies.They collaborate with others to take promising research from labs to market, fund biofabrication startups, pursue patents, and translate research into products.

North America dominated the market in 2022 with an access to advanced technology, private and government funding, and high healthcare spending. Prominent players and 3D tissue engineering advancements fuel growth via continuous product launches. Organogenesis presented the latest wound care research at the 2022 Symposium on Advanced Wound Care Conference. The focus was on PuraPly AM, Affinity, Apligraf, and Organogenesis Physician Solutions. The Biofabrication market is fiercely competitive, with numerous manufacturers vying for a significant share. Prominent players include Danaher, Merck KGaA, Organovo Holdings, Thermo Fisher Scientific, and Sartorius Stedim Biotech.